Hiandri is a CodeMarked system that lifts the whole frame above the floor, keeping bottom plates dry eliminating the need for DPC and allowing unwanted external moisture to escape, helping to ‘future-proof’ the building from expensive repairs and claims!

Skip to

I will be using them all year round

Mark Wilson

Hiandri is a CodeMarked system that lifts the whole frame above the floor, keeping bottom plates dry eliminating the need for DPC and allowing unwanted external moisture to escape, helping to ‘future-proof’ the building from expensive repairs and claims!

Skip to

I will be using them all year round

Mark Wilson

SAVING KIWI BUILDERS THOUSANDS

Our CodeMark approved system rasies the frame above the slab, protecting bottom plates from moisture, eliminating the need for DPC, and allowing drainage preventing costly wet frame delays.

The HIANDRI system has been fully engineered to satisfy the requirements of NZS3604:2011, NZS1170:2002, NZ AS1720.1:2022 their amendments and the Building Code. More importantly HIANDRI packers have CodeMark Certification and are BRANZ appraised. Submitting the CodeMark Certificate and Installation Instructions to the Building Consent Authority (BCA) is an acceptable solution.

How much weight can one packer hold?

Will the plates sag over time or the packers compress over time?

Can you use packers on timber floors?

YES, however the bottom plates must be fixed using 125mm long Type 17 Buildex 14gauge Bugle head screws – Refer to ‘Installation Manual’.

Can the HIANDRI Bottom Plate Packer system be used on 2 and 3 storey buildings?

Do you need a packer under every stud?

Installation Manual

The easy fix for drier frames tag line here

The HIANDRI system has been fully engineered to satisfy the requirements of NZS 3604:2011, NZS 1170:2002, NZS AS 1720.1:2022 their amendments and the Building Code. More importantly HIANDRI packers have CodeMark Certification and are BRANZ appraised. Submitting the CodeMark Certificate and Installation Instructions to the Building Consent Authority (BCA) is an acceptable solution.

Installation Instructions

Acceptable layouts & orientation of HIANDRI packers, for timber and concrete floors.

Fixing Bottom Plates

Further details on fixing bottom plates on concrete and timber floors.

Bracing

Refer to our currently approved bracing systems and recommendations for fixings.

Trusted by builders like you

GENUINE FEEDBACK from real builds

Lorem ipsum dolor sit amet consectetur. Sit sed tempor leo lacinia. A pellentesque sodales odio aliquam. Velit suspendisse nibh eget felis et quis. Tellus orci feugiat turpis est nibh.

I will be using them all year round

On my current job at Omaha, it is not uncommon to get half a metre of sand blown onto the floors over a weekend; we can now just get a blower to remove the sand and any puddled water that has not already escaped, solving a real problem for us.

I’m the first builder in the area to install HIANDRI, and a number of builders I know have called into the site; first comment. – ‘great idea’ – they are now all installing HIANDRI. The owner is also wrapped as he gets the long-term benefits of the product.

I will be using them all year round, having that airflow under the plates is so important. I said to my normal pre-cutter, ‘if you do not install Hiandri bottom plate packers on my frames, I go somewhere else’ that’s how much this innovation means to me – he installed them! I can highly recommend this system to all builders.

Mark Wilson

Hiandri is just a no brainer

Most of our work is alterations and renovations, and putting Hiandri bottom plate packers on site built frames is effortless. It does not seem to matter how old the wall we are replacing is, if it is on a particle board floor, there always seems to be dampness under the plate and rotting flooring – Hiandri solves that problem for sure.

This product has not disappointed, we have already used it on more than one job, and just knowing your timber frames can now drain and dry, is peace of mind for any builder. In fact, we contract to a housing company who, since observing Hiandri on our jobs, is now specifying on all their homes – it’s just a no brainer!

Bruce Walker

It’s going on every frame we erect

The first thing the Building Inspector is going to do, is drive his moisture meter into the bottom plate, who wants to be told, it could be weeks before they can install linings – it’s just a no brainer to use this system!

We used to fire up the heaters and dehumidifiers, and run them at great cost, not to mention the time it took to then straighten the warped frames – those days are now gone. This is our first HIANDRI job, the pre-cutter did not do the top floor – madness; that won’t be happening again, it’s going on every frame we erect from now on, I can assure you of that – great system!

Henri van Berkel

Hiandri comes highly recommended

At the time of construction, I had to engage the services of John Oliver, who is a building consultant, regarding the masonry veneer on this house. John spoke to me about his invention, the HIANDRI bottom plate packer, which I immediately thought was a great idea and decided to install them under my own timber frames, which I did.

Over the past 8 years, John’s HIANDRI system has proved excellent and the system and frames have both performed and met all expectations. In fact, I have had a leaky shower tray that is proving difficult to locate and resolve; the fact that my timber framing is raised 12mm above my concrete floor is proving great insurance as any water will run under the plates and into the brick veneer cavity – in other words, I do not have to worry about my timber frames rotting.

I now understand, that the HIANDRI bottom plate system has been CODEMARKED and I wish HIANDRI Solutions Ltd every success in the future, it comes highly recommended.

Steve Spijkerman

So easy to either put on yourself

Costly heaters and dehumidifiers, that don’t really do the job, re-inspection fees and costly delays, there is no way I want to repeat that experience, now there is a great solution in HIANDRI bottom plate packers. The ideas mint, and so easy to either put on yourself, or have installed; I can assure you, it will be installed on all future jobs I’m involved in.

Rob Harford

REDUCE POTENTIAL DOWNTIME FOR MINIMAL COST

Stay on time, stay on budget. Hiandri bottom plate packers cut out costly pre-line delays by keeping framing moisture under control. No waiting weeks for timber to dry, no pricey heaters or dehumidifiers slowing things down. Just smoother builds, faster finishes, and long-term savings every homeowner will appreciate.

Initial Cost

Installing Hiandri bottom plate packers on a standard 200m² single-storey New Zealand home with 90mm frames adds around $376 + GST. This includes supply and installation of packers ($250 after savings from not needing DPC), plus costs for foam insulation ($80) and longer drive pins ($46). Bolt length requirements generally don’t add cost since most builders already use 135mm bolts. Actual costs may vary depending on design, stud spacing, and frame plant pricing.

Potential Savings

Need more information?

Technical Assistance

Download our Installation Guide or speak to Sam, our specialist located in New Zealand

Keep your frames high and dry

Keep frames out of water

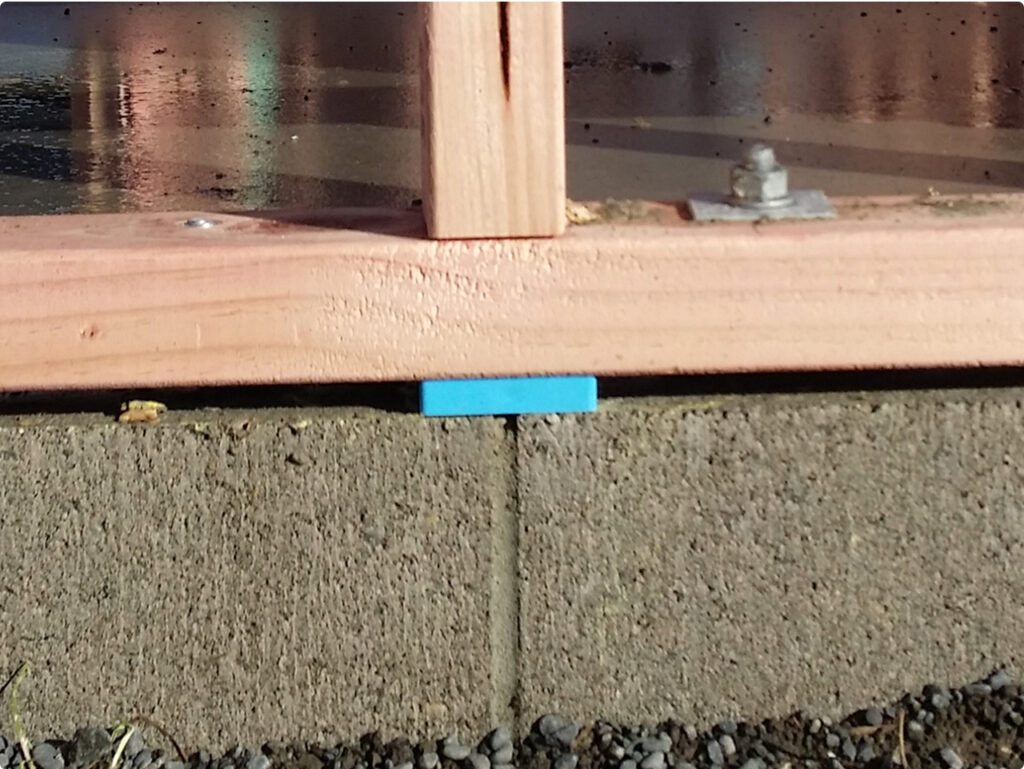

New Zealand climatic conditions can result in high levels of moisture being held in the timber framing for considerable periods of time. A bottom plate, high in moisture content, effectively acts as a barrier to allowing moisture to freely dissipate by gravity through the bottom plate. HIANDRI helps rectify this situation with its 12mm gap.

Initial Cost

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Site Costs

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Potential Savings

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

KEEP YOUR FRAMES HIGH AND DRY

A CodeMarked system that lifts the whole frame above the floor, keeping bottom plates dry eliminating the need for DPC and allowing unwanted external moisture to escape, helping to avoid costly delays with wet frames.

- Keep your frames out of water

- Codemark Certified

- Save on Costly Delays

- Reduce Downtime

- DPC alternative

Why Hiandri?

5 reasons to go hiandri

Reduces building delays at ‘Pre-line’ stage

New Zealand climatic conditions can result in high levels of moisture being held in the timber framing for considerable periods of time. A bottom plate, high in moisture content, effectively acts as a barrier to allowing moisture to freely dissipate by gravity through the bottom plate. HIANDRI helps rectify this situation with its 12mm gap.

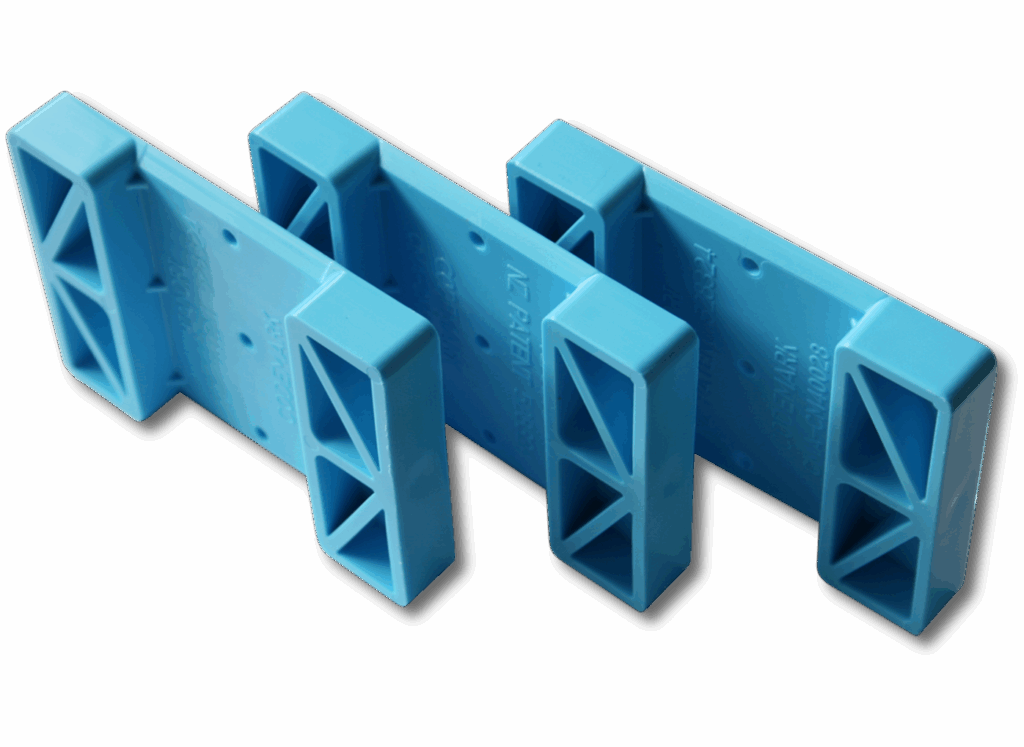

No Damp Proof Course required

The HIANDRI packer is made out of tough, durable polypropylene plastic that cannot absorb moisture, and transfer it to the timber or on to metal framing. It is in reality, a very effective ‘Damp Proof Course’ eliminating the need for traditional DPC’s such as Malthoid. The cost of not having to install traditional damp proof courses, contributes in the order of $150 on an average New Zealand home and goes a long way to off-setting the cost of installing the HIANDRI system PLUS you get all its benefits!

no H3.2 timber bottom plates required

The fact that the timber frames can now drain, dry with air circulation, will never sit in water, the need for H3.2 treated timber bottom plates is unnecessary. The chances of a frame rotting is remote. Specify H1.2 treated timber. This saves about $0.50/m on the timber – just another reduction on the installation cost.

Simplifies bottom plate fixing & improves connections

HIANDRI bottom plate packers are installed using standard bolting systems on concrete floors. The fact that the timber is lifted 12mm off the concrete simplifies the fixing process for the builder.

Provides the build team with a dry, safe working platform

By lifting the bottom plates up 12mm off the floor, it allows water landing on the slab or floor to freely move off the floor and not reach depths up to 45mm when trapped by the bottom plates during heavy rain. In addition, any water that has ponded, can be quickly and simply swept off the building platform under the plates, saving both time and money and a waste of expensive labour.

No Damp Proof Course required

Keep frames out of water

My Manukau Mitre10 rep, Johan Kuypers, first introduced me to HIANDRI bottom plate packers, as he knew what a nightmare of a winter I had been through, with wet timber, especially saturated bottom plates.

Costly heaters and dehumidifiers, that don’t really do the job, re-inspection fees and costly delays, there is no way I want to repeat that experience, now there is a great solution in HIANDRI bottom plate packers. The ideas mint, and so easy to either put on yourself, or have installed; I can assure you, it will be installed on all future jobs I’m involved in.

This is a video block

Save on costly delays

This is a small heading

My Manukau Mitre10 rep, Johan Kuypers, first introduced me to HIANDRI bottom plate packers, as he knew what a nightmare of a winter I had been through, with wet timber, especially saturated bottom plates.

Costly heaters and dehumidifiers, that don’t really do the job, re-inspection fees and costly delays, there is no way I want to repeat that experience, now there is a great solution in HIANDRI bottom plate packers. The ideas mint, and so easy to either put on yourself, or have installed; I can assure you, it will be installed on all future jobs I’m involved in.

Initial Cost

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Site Costs

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Potential Savings

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Fire Rated and Noise Control Walls

HIANDRI Packers have been tested and assessed for use with some GIB® Fire rated walls. These walls are listed below, as is the associated BRANZ Technical Opinion (FC11824-002 ISSUE 2). For confirmation please visit the BRANZ website.

All the Fire rated walls must be constructed as per the GIB® Fire Rated Systems Specification Manual or the GIB® intertenancy Barrier Systems for Terrace Homes (you must then follow the HIANDRI Fire wall details for below the bottom plate level).

Need more information?

Frequently Asked questions

Browse our top questions, or head to our full FAQ page, to find out more.

How much weight can one packer hold?

Will the plates sag over time or the packers compress over time?

Can you use packers on timber floors?

YES, however the bottom plates must be fixed using 125mm long Type 17 Buildex 14gauge Bugle head screws – Refer to ‘Installation Manual’.

Can the HIANDRI Bottom Plate Packer system be used on 2 and 3 storey buildings?

Do you need a packer under every stud?

Technical Assistance

Visit our Cost & Savings page or speak to Sam, our specialist located in New Zealand

Phone

0508 442 6374 - Opt 1

Trusted by over 3,205 Builders like you

GENUINE FEEDBACK from real builds

When it comes to HIANDRI, it’s a “no brainer”

I will be using them all year round

On my current job at Omaha, it is not uncommon to get half a metre of sand blown onto the floors over a weekend; we can now just get a blower to remove the sand and any puddled water that has not already escaped, solving a real problem for us.

I’m the first builder in the area to install HIANDRI, and a number of builders I know have called into the site; first comment. – ‘great idea’ – they are now all installing HIANDRI. The owner is also wrapped as he gets the long-term benefits of the product.

I will be using them all year round, having that airflow under the plates is so important. I said to my normal pre-cutter, ‘if you do not install Hiandri bottom plate packers on my frames, I go somewhere else’ that’s how much this innovation means to me – he installed them! I can highly recommend this system to all builders.

Mark Wilson

Hiandri is just a no brainer

Most of our work is alterations and renovations, and putting Hiandri bottom plate packers on site built frames is effortless. It does not seem to matter how old the wall we are replacing is, if it is on a particle board floor, there always seems to be dampness under the plate and rotting flooring – Hiandri solves that problem for sure.

This product has not disappointed, we have already used it on more than one job, and just knowing your timber frames can now drain and dry, is peace of mind for any builder. In fact, we contract to a housing company who, since observing Hiandri on our jobs, is now specifying on all their homes – it’s just a no brainer!

Bruce Walker

It’s going on every frame we erect

The first thing the Building Inspector is going to do, is drive his moisture meter into the bottom plate, who wants to be told, it could be weeks before they can install linings – it’s just a no brainer to use this system!

We used to fire up the heaters and dehumidifiers, and run them at great cost, not to mention the time it took to then straighten the warped frames – those days are now gone. This is our first HIANDRI job, the pre-cutter did not do the top floor – madness; that won’t be happening again, it’s going on every frame we erect from now on, I can assure you of that – great system!

Henri van Berkel

Hiandri comes highly recommended

At the time of construction, I had to engage the services of John Oliver, who is a building consultant, regarding the masonry veneer on this house. John spoke to me about his invention, the HIANDRI bottom plate packer, which I immediately thought was a great idea and decided to install them under my own timber frames, which I did.

Over the past 8 years, John’s HIANDRI system has proved excellent and the system and frames have both performed and met all expectations. In fact, I have had a leaky shower tray that is proving difficult to locate and resolve; the fact that my timber framing is raised 12mm above my concrete floor is proving great insurance as any water will run under the plates and into the brick veneer cavity – in other words, I do not have to worry about my timber frames rotting.

I now understand, that the HIANDRI bottom plate system has been CODEMARKED and I wish HIANDRI Solutions Ltd every success in the future, it comes highly recommended.

Steve Spijkerman

So easy to either put on yourself

Costly heaters and dehumidifiers, that don’t really do the job, re-inspection fees and costly delays, there is no way I want to repeat that experience, now there is a great solution in HIANDRI bottom plate packers. The ideas mint, and so easy to either put on yourself, or have installed; I can assure you, it will be installed on all future jobs I’m involved in.